PP Honeycomb Board

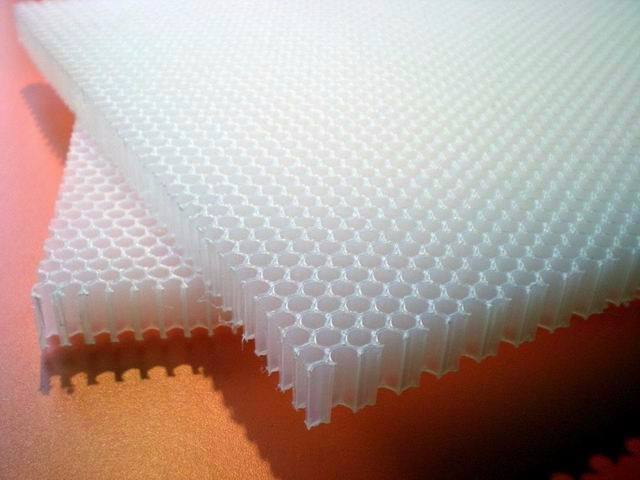

Polypropylene honeycomb board, also called PP hoenycomb sheet is made of two or three thin panels, firmly bonded in a layer of thick honeycomb core material on both sides. The basic raw material is polypropylene, a thermoplastic, recyclable material from the polyolefin group. It is ideally suited to being a semi-finished product that is primarily used to produce sandwich composite components.

Traditional honeycomb is assembled from hexagonal shapes but Polyrocks is the only manufacturer of PP honeycomb in southern China with the circular cell, manufacturing in excess of 3000 tons annually. The unique circular cylinder formation can accept forces from various directions and still maintian shape. These isotropic mechanical characteristics of the individual honeycombs ensure high stability for the whole honeycomb plate and therefore also the final product. Through the use of polypropylene as the initial material, they are resistant to corrosion and their handling is extremely flexible.

As a result of its thermoplastic properties, plastic honeycomb can be shaped thermally and can be cut to the desired shape using conventional tools.The polypropylene honeycombs are ideally suited for use in composites. With suitable processes and resources, virtually all materials can be attached as a cover layer on the honeycombs. Fiber composites(Glass Reinforced Plastics, Glass Mat Reinforced Thermoplastics), metal sheets, wooden plates, High Pressure Laminated cover layers or minerals are frequently used.

Products describe

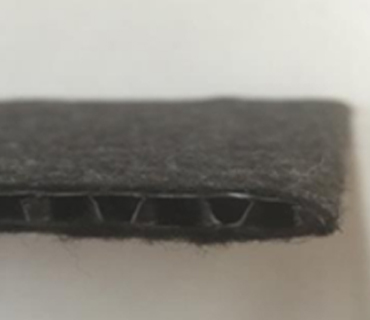

Polypropylene honeycomb board has the advantages of one-step molding, double-sided fabric or leather cover, light weight with high rigidity, non-toxic environmental protection, shock absorption and cold resistance, sound insulation, moisture-proof and heat insulation, etc. It is ideally suited to commercial vehicle construction, boat and ship building, rail vehicle construction, automotive, transport / logistics, construction and wind power systems. It ensures a reduction in mass and at the same time offer particularly high pressure, impact and bending stability, low water absorption and freedom from corrosion. In line with our extensive environmental credentials, polyporpylene is an environmentally friendly plastic as it is 100% recyclable.

Advantages:

a). Strong compressive and impact resistance:

PP honeycomb board absorbs external forces, thus greatly reducing the damage caused by impact and collision. It is widely used in many fields such as automobile bumper and sports protective equipment.

b). Light weight and material saving:

Due to the excellent mechanical performance, the PP honeycomb board can achieve the same standard performance with less consumables, lower cost and lighter weight.

c). Excellent sound insulation performance:

The structure can greatly reduce the diffusion of sound transmission, thus it is being used in vehicles, yachts, high-speed vehicles, vans and construction industry for sound insulation materials.

d). Excellent heat insulation performance:

The internal hollow structure can effectively block the heat transmission, thus makes the internal temperature relatively stable。

e). Water & corrosion resistance:

Due to the characteristics of its raw materials, it can be used for a long time in environments with high water content and strong corrosion.

f). Green and environmental protection:

Energy saving, 100% recyclable, VOC and formaldehyde free in the processing.

Edge Sealing Process

Heat Pressing

Heat Flanging

Sew Sealing

PP Honeycomb Board Production Line

Extrusion Line

Extrusion Line

Application

1. Automobile industry:

PP honeycomb board is widely used in middle and high grade passenger cars and vans as the trunk cover, trunk partition, trunk carpet substrate, car parts cob box, side cob decorative panel, ceiling, car body and other parts.

2. Logistics transfer box:

The light, durable, recyclable and cost effient properties make PP honecomb panel an ideal solution for logistic transfer.

3. Container application:

PP honeycomb board high temperature resistance, strong environmental adaptability, plasticity, easy to assemble.

4. Building decoration industry:

Due to its low density (up to 0.3g/cm3), high strength and excellent sound insulation performance, PP honeycomb board can be used as interior building decoration instead of conventional PVC foam board, building template, wall decoration board, etc., making it the best choice for the new generation of plastic instead of wood materials.

Inquiries

Please leave true info to make sure your feedback works, we will reply you in 24 hours.